As Techtide Solutions, we view product development as the disciplined art of turning uncertainty into value through strategy, engineering, design, and execution. The global appetite for innovation is evident in the fact that total R&D outlays reached 2.48 trillion U.S. dollars in 2022, underscoring why businesses increasingly look to specialized partners to de‑risk the path from idea to launch while preserving speed and quality.

Top 20 product development companies and services to consider

As TechTide Solutions, we work shoulder to shoulder with founders, chief product officers, and engineering leaders navigating the messy middle—turning market insight into manufacturable, supportable, lovable products. Day to day, we back teams that blend strategy with execution, human factors with systems engineering, and reliability with speed.

What separates the best from the rest isn’t design theater or flashy prototypes. It’s how they de-risk complexity, prove value early, and stay in the loop from discovery through scale. For each firm below, we share quick context—focus, size, tenure, base of operations—note independently verifiable recognition, call out service proof where public case work exists, and suggest ideal-fit profiles.

Our aim is to help you triangulate faster: choose a partner whose incentives, capabilities, and working style match your constraints. If useful, we can also map these options to your backlog and stage gates to produce a shortlist tailored to your roadmap.

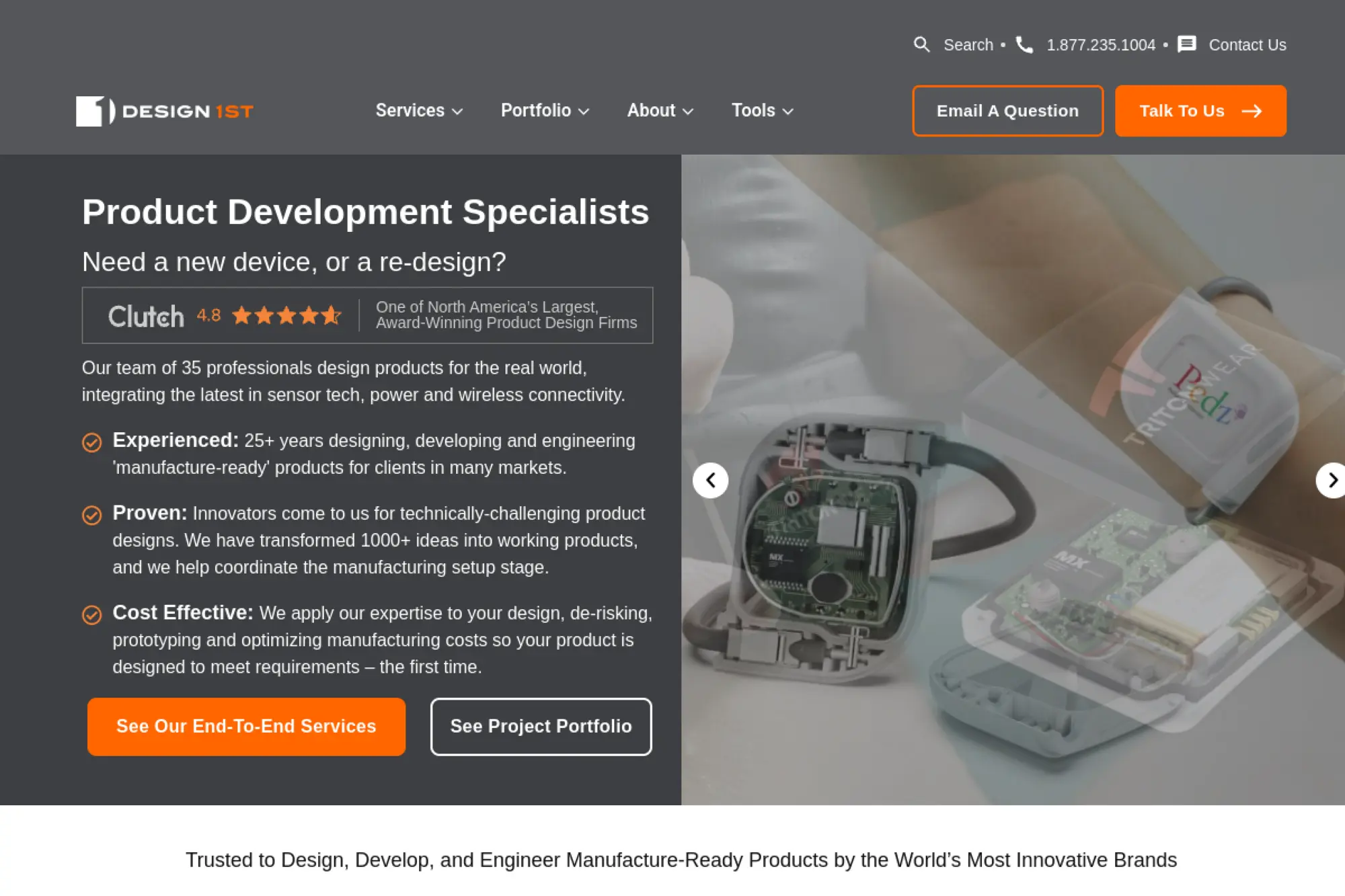

1. Design 1st

Overview: A Canadian product development consultancy focused on electromechanical devices, connected hardware, and industrial design, Design 1st operates with an estimated 35–60 employees and has been active since 1996 (~29 years). The company is headquartered in Ottawa, Ontario, with additional presence across major Canadian tech hubs. Their sweet spot is taking complex physical concepts from feasibility through DFM and pilot production while keeping a sharp eye on reliability and cost-of-goods.

Awards: The firm’s work has been publicly recognized; notably, it received the 2011 Solution of the Year from Ottawa’s innovation community, a regional honor that underscores its role in supporting commercialization for growth‑stage companies.

Services & proof: Design 1st’s portfolio spans medical wearables, industrial sensors, and consumer devices; where public proof exists, you’ll see shipped work across safety systems, connected pumps, and robotics. The team is comfortable bridging industrial design with mechanical engineering and supplier onboarding, which matters when tolerance stacks collide with brand promises.

Ideal Fit: North American startups and midsize manufacturers needing an experienced build partner for electromechanical products, particularly when reliability testing, regulatory foresight, and transfer‑to‑manufacturing support must happen in lockstep with design.

2. LA NPDT

Overview: LA New Product Development Team is a hybrid hardware/software product studio serving entrepreneurs and SMEs across consumer, industrial, and wellness categories. With roughly 20–40 professionals active for ~9 years, the company originated in Shreveport, Louisiana, and has since broadened its footprint as it added low‑volume manufacturing and DFM capability. Their work leans pragmatic—solving manufacturability and small‑batch scale questions earlier than most studios.

Related Posts

- Top 30 App Development Companies In Spain 2026

- Top 30 Mobile App Development Companies in France to Consider

- Top 30 Outsourcing Software Development Companies in Vietnam: Comparison, Vendors, and How to Choose

- Top 30 Cybersecurity Companies In Vietnam For 2025

- Top 30 custom application development companies in 2025: research-based shortlist and buyer’s guide

Awards: The team’s charging dock concept earned a Gold Medal at iCan 2020, an international ideas and inventions competition, highlighting their prototyping agility under tight constraints.

Services & proof: In the public domain, LA NPDT shows small‑run manufacturing, molding, and contract assembly capabilities—useful for pilot sales, compliance prototyping, or channel tests before committing to full tooling. We’ve seen their practical “value engineering” stance help founders avoid death‑by‑BOM on first production runs.

Ideal Fit: First‑time founders and small firms that need soup‑to‑nuts support—CAD, prototyping, EVT/DVT assembly—and realistic unit economics before they invest in hard tooling, especially for accessories, simple mechatronics, and wellness devices.

3. TechTide Solutions

Overview: We’re a software development company specializing in cloud‑native platforms, mobile/web applications, and the data plumbing that keeps products useful after launch. With about 150 full‑time professionals and ~10 years in market, we’re based in Ho Chi Minh City and work globally. Our focus areas include fintech, healthcare, blockchain‑adjacent data services, and insurance tech—domains where availability, auditability, and integration matter.

Awards: We typically channel recognition into client outcomes rather than the awards circuit, so we’ll let the shipped platforms speak for themselves. When a client needs third‑party validation (e.g., for a fundraising or procurement event), we prioritize reliability metrics, SLAs, and security attestations over trophies.

Services and proof: Our teams ship greenfield MVPs and modernization work alike. We deliver Kotlin and Swift mobile, React and Next.js fronts, and JVM, .NET, and Node backs. Meanwhile, AWS and GCP, infrastructure as code, and strong observability underpin these builds. Often, teams call us when velocity stalls behind monoliths, test debt, or unclear data lineage. A blend of platform engineering, QA automation, and instrumentation multiplies signal per sprint by ten.

Ideal Fit: Product leaders who want hands‑on execution and credible architectural runway—Series A to post‑scaleup—across regulated or complex ecosystems, working in iterative releases with measurable adoption and reliability targets.

4. StudioRed

Overview: A Silicon Valley product development consultancy, StudioRed blends industrial design, mechanical engineering, UX/UI, and prototyping. Founded in 1983 (~42 years) and based in the Palo Alto/Menlo Park area, the team runs lean (≈30–50 people) and focuses on bringing manufacturable, brand‑correct products to life for consumer electronics, retail experiences, and med‑tech.

Awards: StudioRed’s design work for 7‑Eleven’s checkout technology has been recognized with an iF DESIGN AWARD, a third‑party validation of the team’s ability to marry human‑factors and operational throughput in high‑traffic contexts.

Services & proof: Public case examples include retail self‑service systems and connected consumer devices, where they typically carry concepts through CMF, engineering for assembly, and jig/fixture design. Their in‑house prototyping allows faster form/fit cycles—useful when human‑in‑the‑loop use cases hinge on subtle geometry, weight, and tactile feedback.

Ideal Fit: Brands or scaleups with clear go‑to‑market plans who need a design‑engineering partner experienced in channel realities, POS constraints, and cost‑optimized assemblies—especially for electronics that must survive real‑world abuse.

5. Goddard Technologies

Overview: Goddard is a med‑device and life‑science product development firm known for integrating industrial design, systems engineering, and low‑volume manufacturing. Founded in 1997 (~28 years), they’re headquartered in Beverly, Massachusetts, with a West Coast office in San Diego. With ≈100+ people, they are fluent in IEC/FDA expectations, risk management, and human factors for Class I–III devices.

Awards: Goddard’s recognition tends to show up in regulatory milestones and adoption rather than the general awards circuit—common among disciplined med‑tech firms whose biggest “wins” are clinical, compliance, and market outcomes.

Services & proof: Publicly documented projects span surgical tools, diagnostics workstations, and wearable NPWT systems, including support for OR‑validated ergonomics and sterile workflows. We’ve seen their low‑volume manufacturing bridge the gulf between alpha builds and clinical pilots without losing design intent.

Ideal Fit: Venture‑backed or established med‑tech teams that need an experienced design control partner across verification/validation gates, DHF completeness, and supplier qualification, with the ability to stand up pilot lines.

6. Ranosys

Overview: A digital engineering and commerce services firm with roots in Singapore and delivery hubs in India, the UK, and the US, Ranosys has scaled to ~500+ employees over ~15 years. They focus on enterprise platforms—Adobe Experience Cloud (including Adobe Commerce), Salesforce, Microsoft, and headless/microservices stacks—often unifying content, commerce, and personalization.

Awards: Ranosys has received recognition from major platform ecosystems; their Adobe partner awards are documented in the ecosystem and press, reflecting delivery depth on complex enterprise programs.

Services & proof: Public client stories show B2C/B2B commerce re‑platforming, AEM rollouts, and data‑driven lifecycle marketing. If you’re wrestling with catalog complexity, multi‑site governance, or SAP/OMS integration debt, a partner like Ranosys brings playbooks and certified squads to compress risk.

Ideal Fit: Mid‑market and enterprise teams seeking a platform specialist to align content/commerce stacks with KPI‑tied journeys, or to migrate legacy Magento/SFCC/monolith commerce to scalable, instrumented architectures.

7. Simplexity

Overview: Simplexity is a West Coast engineering firm specializing in mechatronics, embedded systems, and motion control. With offices from San Diego to Seattle and ~100+ professionals active for ~15–20 years, the team excels at multi‑disciplinary electromechanical integration—where firmware, mechanical, and control systems must sing in tune.

Awards: Their emphasis is on ISO‑backed quality and on‑time NPI rather than public awards, which matches the temperament of teams whose work gets buried inside lab automation equipment and medical devices that just have to work.

Services & proof: Public cases show automated DNA sample extraction stations, wearables, and microfluidics. In our experience, their value shows up in “first‑principles” rigor—e.g., chasing tolerances through a drive train plus sensor fusion to nail repeatability at cost.

Ideal Fit: Companies with precision motion, robotics, or instrument design challenges who need a systems engineering partner to de‑risk control loops, throughput, and manufacturability without ballooning BOM or calibration cost.

8. AJProTech

Overview: A full‑cycle hardware and IoT studio headquartered in Los Angeles with satellite presence in Taiwan and Central Asia, AJProTech operates with ~40–60 engineers and ~10 years in market. They take consumer and industrial electronics from feasibility through certification and into low‑to‑mid‑volume production, often bundling firmware, app, and cloud development.

Awards: The studio’s work has earned 2 iF AWARDS in recent cycles, signaling international peer review across product categories and validating their industrial design + engineering blend.

Services & proof: Public case studies include a smart basketball hoop, neurofeedback devices, and biometric capture systems; in each, you see supply‑chain pragmatism—sourcing, DFM, and cost control—deployed alongside BLE stacks, app UX, and analytics.

Ideal Fit: Startups and product leaders needing a single accountable team to converge industrial design, EE/ME, firmware, and app layers—especially when you must validate unit economics in parallel with user value.

9. Ziba

Overview: Ziba is a Portland‑based innovation and design consultancy founded ~40 years ago, known for brand‑led product and service experiences. Employee count sits around 50–100, with cross‑functional talent spanning research, brand systems, industrial design, and digital build. Ziba’s hallmark is deep ethnography that translates into coherent multi‑touchpoint systems.

Awards: Ziba’s client work has long been recognized across global design programs; their emphasis tends to be on client outcomes (market share, retail conversion, care experience) rather than medaling per se.

Services & proof: Public work features healthcare digital strategy, retail brand systems, and peripherals/input for global tech brands. We’ve seen their strength in defining the “grammar” of an ecosystem—so new products, screens, and spaces speak the same language.

Ideal Fit: Leaders who need research‑to‑roadmap translation plus design language systems that travel across hardware, apps, and environments—especially when the brand must hold together during aggressive portfolio expansion.

10. Smart Design

Overview: Founded in 1980 and headquartered in New York City, Smart Design is a multidisciplinary consultancy. The team numbers roughly 100 to 200 people. They are known for user centered industrial design and systems thinking. Their legacy includes consumer icons and civic design programs. The approach treats ergonomics and inclusivity as profit levers.

Awards: Smart Design received Cooper Hewitt’s 2010 Product Design National Design Award, a signal honor that recognizes a body of work reshaping everyday behaviors (think OXO Good Grips or humanized auto HMIs).

Services & proof: Public programs include kitchen tools that mainstreamed universal design. Additionally, transportation graphics reshaped city wayfinding. Finally, medical platforms were refined for sterile, gloved workflows. Their secret sauce is cultivating “design empathy” within client teams, not just delivering assets.

Ideal fit: organizations committed to inclusive design and measurable usability. They aim to reshape categories through ergonomics, CMF, and behavior aware workflows in consumer and medical.

11. IDEO

Overview: IDEO is a global design and innovation firm founded in 1991. It has more than 500 employees across the US, Europe, and Asia. Historically based in the Bay Area, it is synonymous with design thinking. The team blends research, rapid prototyping, and business design to tackle products, services, and organizational change.

Awards: The firm was honored with Cooper Hewitt’s 2001 Product Design National Design Award, reflecting decades of influence from early computing peripherals to service and healthcare redesign.

Services & proof: Public lore includes Apple’s early mice, mobile hardware, and pharmacy experiences that reimagined fulfillment and adherence. In our view, IDEO’s durable contribution is less a deliverable and more a repeatable way to reduce uncertainty when markets and behaviors are shifting.

Ideal fit: enterprises facing ambiguous problem spaces, from new ventures to service reinvention and cultural transformation. They need structured discovery with stakeholder buy in and credible prototyping paths to de risk investment.

12. Speck Design

Overview: Speck Design is a Silicon Valley product design firm (~30+ years, ~50–100 people) specializing in industrial design, UX, and engineering for consumer and industrial systems. Headquartered in San Jose, the team often works at the human‑machine interface where brand, usability, and reliability meet constraints.

Awards: Speck’s design collaboration on a 3M water dispenser is recognized with an iF DESIGN AWARD, a program noted for cross‑jurisdictional juries and rigorous multi‑criteria evaluation.

Services and proof: Public cases include automated food retail, hydration and filtration, and hydrogen fuel cell accessories. These show a team comfortable with digital interactions and high touch physical ergonomics.

Ideal fit: product leaders needing end to end authority across research, industrial design, EE and ME integration, and vendor collaboration. Compress time to retail ready or field ready products without sacrificing brand truth.

13. Accenture

Overview: Accenture is a global professional services firm headquartered in Dublin, Ireland, in its current form since 1989. Today, the company employs roughly 770,000 people worldwide. Across strategy, digital, cloud, data and AI, and operations, it serves nearly every major industry. Often, Accenture acts as the prime contractor on multi-year transformation programs.

Awards: Accenture is recognized by Brand Finance as the most valuable IT services brand in 2025, a branding and market‑strength acknowledgment, and ranked 6 on Great Place to Work’s World’s Best Workplaces 2024, reflecting sustained employer reputation across countries.

Services & proof: Public case libraries span customer‑experience overhauls, cloud migrations, and AI‑enabled process redesign. When your initiative touches 20+ systems, multiple regions, and regulatory overlap, Accenture’s scale—frameworks, assets, and governance—can be an accelerant.

Ideal fit: Fortune 1000 enterprises needing a large, multidisciplinary partner with global delivery for mission critical transformations. Includes operating model shifts and platform consolidations with measurable value capture.

14. ARC Technology Solutions

Overview: ARC is a Nashua, New Hampshire‑based engineering services company (~26 years) focused on automated test equipment (ATE), torque/process verification, and factory productivity tooling. With ~50–100 staff, they specialize in integrating smart tools and RF/functional test systems for aerospace, defense, and complex electronics.

Awards: ARC’s credibility shows up in customer productivity outcomes, adherence to ITAR‑related protocols, and longevity in high‑reliability markets rather than participation in general design award circuits.

Services & proof: Public information highlights torque integration for jet engine assembly, mixed‑signal testers, and traceability systems. For manufacturers wrestling with NCMR rates, their PVS/DSX approaches help enforce sequence, capture proof, and close the loop with MES/ERP.

Ideal Fit: Ops leaders in aerospace or advanced manufacturing who need custom test rigs, error‑proofed assembly, and data‑rich process verification that pays for itself in scrap reduction and audit readiness.

15. BiTE Interactive

Overview: BiTE Interactive is a North American mobile and software consultancy with about fifteen years in business and roughly twenty to fifty staff. The firm emphasizes behavior driven development, onshore teams, and accessibility. Additionally, it operates from US and Canadian hubs, delivering native and cross platform applications for finance, health sciences, and public sector use cases.

Awards: BiTE’s emphasis has been on engineering discipline and reliability rather than awards. Their public posture highlights BDD and continuous delivery as risk reducers for enterprise mobile programs.

Services & proof: Public references cite Fortune grade clients and IoT programs beyond phone assumptions. Meanwhile, Android embedded work shows behavior diverging from typical handset norms. Additionally, for legacy mobile codebases, expect confident refactoring or takeovers. Finally, they will say no when scope threatens quality.

Ideal Fit: Product owners who value explicit acceptance criteria, high‑signal test automation, and onshore collaboration for mobile, IoT, or cross‑platform apps that must integrate deeply with enterprise back ends.

16. Frog

Overview: Founded in 1969 and now part of Capgemini Invent, frog is a global design consultancy. Studios span the United States, Europe, and Asia. Headcount fluctuates with integration, but the network includes hundreds of practitioners. Roots in industrial design expanded into brand, digital products, and venture creation across many sectors.

Awards: frog’s legacy includes being named Red Dot’s Design Team of the Year (Hall of Fame listing: 1993), highlighting its foundational impact on product design and design leadership over decades.

Services & proof: Public histories cover Apple’s “Snow White” design language, healthcare platforms, and mobility experiences. We’ve seen frog’s value in aligning executive vision with shippable roadmaps—bridging service, product, and brand into one narrative that engineering teams can action.

Ideal Fit: Large organizations and scaleups that need executive‑level reframing plus the muscle to run discovery through pilot, especially for multi‑modal experiences that cross devices and environments.

17. Abalta Technologies

Overview: Abalta is a San Diego‑based mobility software company (~20+ years; ~100 staff) known for smartphone‑to‑vehicle connectivity (WebLink), cloud back ends, and automotive HMI integration. They work across Tier 1s and OEMs to bridge consumer devices, embedded systems, and the vehicle UX.

Awards: Abalta has received workplace recognition and ecosystem nods; in our experience, their most telling validation is the multi‑year adoption of their connectivity stack within infotainment systems that ship in the millions.

Services & proof: Public material highlights connective middleware and host apps that expose smartphone experiences in head units, plus content partnerships and developer tooling to keep UX fresh over vehicle lifecycles. It’s the messy glue that keeps drivers happy while respecting safety and regulatory boundaries.

Ideal Fit: Automotive ecosystem players—Tier 1s, OEM innovation teams, and mobility startups—who need pragmatic smartphone integration, content partnerships, and OTA lifecycle management without fragmenting user experience.

18. Brash

Overview: Brash Product Development Inc. is a North American design‑engineering studio focused on connected devices, wearables, and medical/assistive products. Operating for over a decade with an estimated team size of 20–40, Brash is headquartered in Canada and collaborates across startups and growth‑stage companies, often engaging from concept through pilot production.

Awards: The studio cites third‑party honors across product and IoT categories; their most meaningful achievements tend to be clinical adoption and channel wins for early‑stage clients rather than trophy counts.

Services & proof: Public work shows IoT trackers, dental/wellness devices, and assisted‑living systems. What we appreciate is their emphasis on validating use cases early—building test harnesses and hero prototypes so that usability and cost targets inform the engineering stack, not follow it.

Ideal Fit: Founders and product leaders who want a nimble team to marry attractive industrial design with EE/ME pragmatism, including pre‑compliance testing and early supply‑chain fit for medical‑adjacent or regulated categories.

19. Code and Theory

Overview: Code and Theory is a digital‑first creative and technology partner (~1,000+ staff; ~24 years), headquartered in New York with a global footprint. The firm combines brand systems, content platforms, and complex front‑end engineering to serve media, sports, retail, and public‑sector clients—often at “internet scale” where resiliency and editorial velocity matter.

Awards: The agency earned three distinctions in 2025 from Fast Company’s Innovation by Design Awards, reflecting sustained recognition across product and experience categories.

Services & proof: Public cases include an election‑night data experience capable of ingesting live results from thousands of jurisdictions, and a reimagined NFL app oriented around video‑first engagement. From our vantage point, their strength is aligning editorial, design systems, and performance engineering so content and commerce can scale without brittle governance.

Ideal Fit: News, sports, and enterprise brands with high‑stakes experience platforms—where speed, accessibility, and consistency across devices are non‑negotiable, and where design and engineering must operate as one team.

20. Digital Scientists

Overview: Digital Scientists is an Atlanta‑area product and AI consultancy (~18 years; ~80+ people) focused on custom software, platform modernization, and applied AI for healthcare, logistics, and public sector. With hybrid nearshore delivery, they combine discovery, design, and engineering to accelerate MVPs and modernize legacy systems pragmatically.

Awards: Their reputation is built on program outcomes and long‑running client relationships, rather than awards circuits—a common thread among firms embedded deeply in enterprise modernization.

Services & proof: Public references include work for healthcare distributors, retail platforms, and field service networks, with emphasis on measurable ROI—reducing cycle time, unlocking data visibility, and building IP that customers own. We value their insistence on instrumented baselines so “improvement” is observable and defensible.

Ideal Fit: Leaders with platforms that must evolve—where a blend of product thinking, technical debt pay‑down, and data/AI integration can deliver adoption and efficiency gains within the same fiscal year.

If you’d like, we can align these options to your roadmap: share your target launch dates, compliance constraints, and the two or three “can’t‑fail” jobs your product must accomplish, and we’ll propose a staged vendor shortlist—with tradeoffs and budget bands—for your next build cycle. Which two companies above feel most aligned with your current challenge, and why?

What product development companies do and how the process works

The best partners think and build in systems, not silos. Strong design and engineering capability is not a cosmetic advantage; top design performers have been shown to deliver 32 percentage points higher revenue growth, a signal that craft and commercialization are intertwined. With that lens, here’s how the work usually flows in practice.

1. Idea generation and product strategy

We start by framing the problem space before falling in love with any solution. Define the job customers hire the product to do. Map the competitive landscape and real channel constraints. Then stress test hypotheses against brand posture and regulatory paths. Capture it in a living product strategy with measurable outcomes and design principles. That way, the team never mistakes motion for progress.

2. Market research and customer discovery

We blend ethnography, workflow shadowing, and lightweight experiments to validate desirability and viability early. Often, founders ask for a silver bullet. Instead, we find lead bullets work better: structured interviews, artifact walkthroughs, and prototype driven conversations that surface unspoken customer needs. Done well, research becomes a force multiplier for later engineering choices by clarifying acceptance criteria up front.

3. Industrial design and human factors

Industrial design translates strategy into form, materials, and interaction patterns that make the product intuitive, trustworthy, and delightful. Human factors work turns usability risks into testable questions: how the product is grasped, navigated, cleaned, repaired, and disposed of. In safety critical categories, we formalize the work with risk driven usability plans and traceability. Findings map directly to design changes. This is not paperwork theater. It is evidence of sound decisions.

4. Mechanical, electronics, and embedded software engineering

Our default is modular architecture: isolate fast‑changing subsystems (like firmware and wireless stacks) behind crisp interfaces and keep the slow‑changing ones (like enclosures and power delivery) stable. We model noise, heat, and tolerance sensitivities early to avoid surprises in pilot builds. For embedded software, we design for observability from day one, so field issues can be diagnosed without disassembling the product or guessing from vague error states.

5. Prototyping and validation testing

We use prototypes to answer the cheapest possible question at each stage. Looks like models help drive executive alignment and channel feedback. Meanwhile, works like rigs reduce risk in physics and performance. Next, final like units prove assembly, reliability, and serviceability. A healthy prototype plan staggers these artifacts and pairs each with a decision gate. Therefore, the team resists polishing when it should be learning.

6. Product architecture and systems integration

Systems integration is where elegant diagrams meet messy reality. Integration sprints flush out impedance mismatches between mechanical tolerances, sensor precision, wireless coexistence, and cloud back ends. We treat requirements as interfaces, not wishes, and instrument the integration lab so the product can tell us what it’s doing instead of making us reverse‑engineer symptoms.

7. Design for manufacturing and transfer to manufacturing

Great products die in the gap between engineering intent and factory truth. We design parts for process capability. We plan inspection methods that mirror the physics that truly matter. With suppliers, we align on golden samples to anchor taste debates. Successful transfer requires a clear playbook. Include tooling kickoff, fixture design, and precise work instructions. Add inline test design and a yield ramp plan. Anticipate where the first defects will appear.

8. Supplier sourcing and parts strategy

Supplier selection is product design by other means. We weigh process maturity, material pedigree, and responsiveness under pressure, then shape the bill of materials to minimize single‑point fragility. Preferred‑part libraries, lifecycle plans, and second‑source options are not administrative niceties; they’re insurance policies against obsolescence and supply shocks.

9. Regulatory pathways and quality assurance

Regulation is a systems constraint, not a last‑mile hurdle. We map applicable frameworks early, build a traceable risk register, and ensure verification methods mirror real use environments. Auditors look for coherent stories: consistent requirements, evidence that risks were mitigated, and proof that critical characteristics are controlled in production.

10. New product introduction and launch planning

NPI aligns marketing, support, operations, and finance around the first shippable experience. We choreograph pilot runs, channel seeding, and service readiness so the first customers become advocates rather than beta testers. Good NPI balances ambition with staged exposure, using defined feedback loops to harden the product before broad availability.

11. Post-launch support and continuous improvement

Launch is not an endpoint; it’s a new dataset. Telemetry flows into a triage model that separates noise from systemic issues. We feed those insights into a living maintenance roadmap. The loop spans more than tech: content, support scripts, and channel enablement evolve with the product’s story.

How to choose among product development companies: criteria and pitfalls

Selection mistakes are expensive and demoralizing. Many products fail for avoidable reasons; a widely cited analysis of post‑mortems found that 42% of startups fail due to no market need, which is why discovery rigor, not just engineering horsepower, should loom large in your criteria.

1. Industry expertise and experience

Ask for evidence that the team understands your category’s quirks: channel dynamics, service models, compliance norms, and the unwritten rules competitors already exploit. We also look for the humility to adapt patterns from adjacent domains, not force‑fit one signature style everywhere.

Our top twenty shortlist (balanced across design studios and ER&D leaders)

- IDEO

- frog

- Cambridge Consultants

- PA Consulting

- TTP

- Cambridge Design Partnership

- Sagentia Innovation

- EPAM Continuum

- Teague

- Whipsaw

- fuseproject

- Design Partners

- Capgemini Engineering

- Accenture Industry X

- HCLTech Engineering and R&D Services

- L&T Technology Services

- Tata Elxsi

- Wipro Engineering Edge

- Infosys Engineering Services

- Siemens Advanta

We’ve partnered with and competed against many of these firms; strengths vary by category, so match the shortlist to your use case rather than brand gravity alone.

2. Technical skills and innovation capability

Probe for architectural thinking and the ability to prove or kill assumptions early. We favor teams that can show working rigs, not just renderings, and that can explain tradeoffs in plain language. A credible partner can span from materials and mechanisms to cloud and mobile without treating integration as an afterthought.

3. Project management and communication

Look for crisp status rituals, transparent risk logs, and asynchronous updates that survive time zones. The most valuable artifacts are living: decision records, interface specs, and test plans that evolve as the product learns.

4. Scalable solutions and resource depth

Your partner should flex capacity without turning your roadmap into a staffing exercise. We ask how they handle spikes, holidays, attrition, and specialized needs like EMC troubleshooting or design verification, and we expect honest responses about when they’ll bring in specialist suppliers.

5. Budget and cost transparency

Insist on cost models that separate recurring from non‑recurring work and clarify how design choices affect unit economics. Great partners make cost a design variable, not an uncomfortable surprise.

6. Project timeline and delivery track record

Schedules should be argumented, not asserted. We examine the chain of dependent bets, the size of learning loops, and whether the plan anticipates integration friction. A believable timeline also names the exit criteria for each gate.

7. Post-launch support commitments

Products live in the field. Ensure your partner commits to sustaining engineering, security updates, and managed transitions when components go end‑of‑life. The maintenance plan is as much about relationships as it is about code or parts.

8. Manufacturing and compliance readiness for your category

We want to see early engagement with contract manufacturers, test labs, and notified bodies where relevant. A firm that invites auditors and factory engineers into the conversation before design freeze is signaling respect for reality.

9. PLM and ALM toolchain and digital thread maturity

Ask how requirements flow into CAD, how firmware versions link to hardware revisions, and how suppliers receive up‑to‑date specs. A mature digital thread reduces misbuilds, accelerates failure analysis, and preserves institutional memory when teams change.

10. Design to value and cost modeling discipline

Cost is not the enemy of quality; indifference is. We look for parametric models tying part features to process steps and yield assumptions, plus teardown insights from benchmarks to avoid gold‑plating where customers don’t notice.

11. New product introduction and supply chain coordination

Good NPI is choreography: procurement, quality, manufacturing engineering, and logistics moving in step. Review how your partner plans pilot builds, line bring‑up, and issue triage across organizations that don’t share tools or incentives.

12. When to outsource versus build an internal product team

Outsource when speed, specialized capability, or capital efficiency dominate. Build in‑house when the capability is a durable differentiator or when high‑tempo iteration post‑launch demands embedded context. Hybrid models work well: keep product management and critical architecture internal while partnering on design, verification, and transfer.

TechTide Solutions: custom product development aligned to customer needs

We designed Techtide Solutions to operate as a full‑stack partner: research to roadmap, prototype to line bring‑up, launch to lifecycle. Our cloud‑native approach reflects the reality that many products now ride software and connectivity; public cloud adoption trends point to sustained investment, with end‑user spending projected to total $723 billion in 2025, which is why we architect for observability, security, and scale from the outset.

1. Tailored discovery and solution architecture for your product vision

We begin with an immersion that frames outcomes, risks, and constraints, then translate that into an architecture that isolates volatility. Where uncertainty is high, we plan learning sprints and define the minimum demonstrable proof that will unlock the next decision. Our north star is not a document; it’s a shared mental model captured in artifacts everyone can critique.

2. Rapid prototyping, iterative development, and user validation

We move from bench to field quickly using modular prototypes and instrumented firmware. When a question is best answered by a customer in context, we take it to them with a testable artifact. Our engineers expect to rewrite and refactor; speed is achieved by shrinking the cost of change, not by pretending change won’t happen.

3. Integration, scalability, and long‑term support to meet business goals

Our integration labs mirror the complexity of the real world: wireless congestion, hostile power conditions, and noisy environments. We plan for lifecycle realities such as component obsolescence and evolving security expectations, and we build sustaining engineering into the contract so improvement does not rely on heroics.

Conclusion: choosing the right product development company for your next build

Choosing well is a strategic advantage. Market signals suggest external partnerships will remain central to transformation agendas, with 80% of executives are planning to maintain or increase investment in third-party outsourcing, which makes vendor selection a board‑level decision rather than a procurement footnote.

1. Key takeaways on product development companies

Great partners integrate research, design, engineering, and manufacturing into a single learning loop. They treat cost as a design variable, regulation as a systems constraint, and post‑launch as the beginning of a richer feedback cycle. Above all, they make their decision logic visible so you can trust how the sausage is made.

2. How to shortlist and evaluate vendors

Anchor your search on category fit, integration chops, and evidence of learning velocity. Ask for artifacts, not just promises, and request a small paid discovery to evaluate how the team collaborates under real constraints. References matter; so do the questions vendors ask you, because they reveal what they will optimize for when tradeoffs bite.

3. Next steps to move from idea to MVP

If you’re ready to explore, we suggest a lightweight discovery sprint focused on clarifying outcomes, mapping risks, and identifying the few proofs that will unlock momentum. Shall we co‑create a brief to pressure‑test your concept and define the first build that customers will love?